Kano lab.

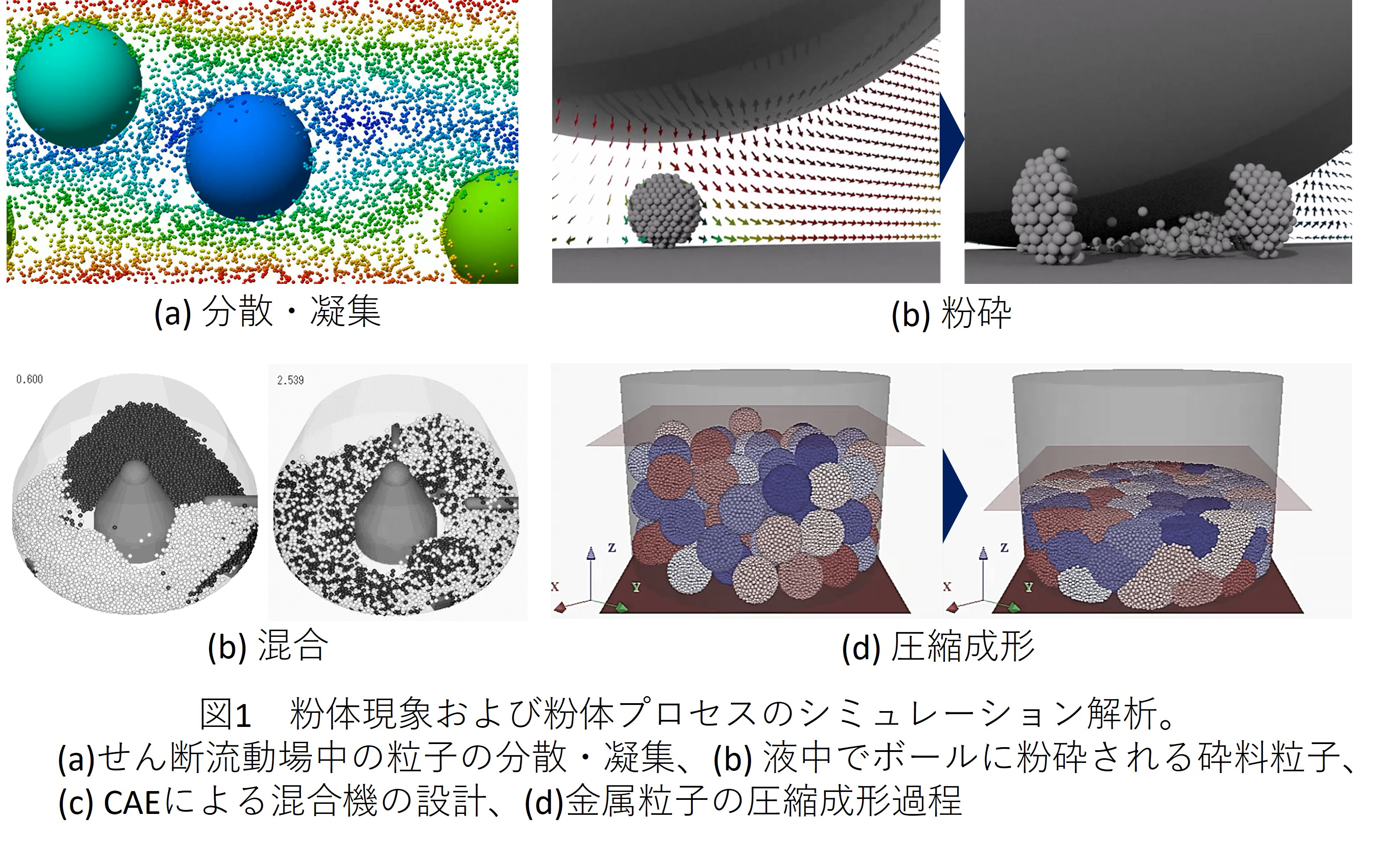

Development and manufacture of high functional materials have been actively made, and most of those raw materials, intermediate products and final products are particulate materials. The properties of the high functional materials are greatly dependent on the particle packing structure in the materials as well as those chemical compositions. The particle packing structure is also highly dependent on the particle properties and characteristics such as particle size and its distribution of the particles, which depend on their preparation processes. Therefore, in order to obtain the function desired, first of all, the preparation process of the particles as a raw material should be elaborately controlled, and then the powder processing such as mixing, filling, forming and composite must be controlled exquisitely. In our laboratory, we are carrying out development of numerical simulation method for control of powder processing. Optimizing the powder processing by the simulation is performed for energy saving and resource saving. In addition, we are developing processes for recycling of metals from urban mines and for hydrogen energy generation from biomass and plastics by using the mechanochemical effects which are obtained in the grinding process.